What Size Air Compressor Do I Need For Air Tools (With Chart)

An air compressor is an essential tool for any workshop or garage especially if you are working with air tools. But one of the most commonly asked questions when buying an air compressor is, What size air compressor do I need for air tools?

The answer to this question depends on a variety of factors including the type of air tools you will be using, the amount of air pressure and volume required by those tools, and the size of the air tank. In this article, we will explore all of these factors and help you determine the right size air compressor for your air tools. So, without any further ado let's take a look at it.

Factors to Consider When Getting An Air Compressor:

Below are some things to consider when getting an air compressor for yourself.

Type Of Air Tools:

The type of air tools you will be using is the most critical factor to consider when choosing the right size air compressor as different air tools require different amounts of air pressure and volume to operate efficiently.

For instance, a pneumatic impact wrench requires a higher volume of air than a pneumatic drill. Therefore, you need to determine the type of air tools you will be using and their air pressure and volume requirements.

Air Pressure And Volume:

The air pressure and volume requirements of your air tools are also critical factors to consider. PSI (pounds per square inch) is the unit used to measure air pressure, while CFM (cubic feet per minute) is the unit used to measure air volume.

The air pressure and volume requirements for each tool are usually listed in the manufacturer's specifications so you need to ensure that the air compressor you choose can deliver the required air pressure and volume for your tools to operate efficiently.

Air Tank Size:

The air tank size is another critical factor to consider when choosing an air compressor as the air tank is responsible for storing compressed air, which is then used to power your tools.

The size of the air tank determines how long your compressor can maintain a steady supply of compressed air and if you are using tools that require a lot of air volume, you will need a larger air tank to ensure that your compressor can keep up with the demand.

Calculating The Air Compressor Size:

Calculating the right size air compressor for your needs requires a bit of math and here's how to do it:

Determine The Required CFM Of Your Air Tools:

To determine the CFM requirements of your air tools you need to add up the CFM requirements of each tool you will be using simultaneously.

For instance, if you will be using an impact wrench that requires 5 CFM and a spray gun that requires 7 CFM you will need an air compressor that can deliver at least 12 CFM. Try to get an air compressor that can deliver 2 or 3 times more than the required CFM so you can perform your tasks more efficiently.

Determine The Required PSI:

The required PSI for your air tools is usually listed in the manufacturer's specifications so you need to ensure that the air compressor you choose can deliver the required PSI for your tools to operate efficiently.

Calculate The Tank Size:

To calculate the required tank size, you need to consider the duty cycle of your air tools. The duty cycle is the percentage of time your tools will be in use.

For instance, if your tools will be in use for 50% of the time you will need an air compressor with a tank size that can provide enough compressed air for the other 50% of the time.

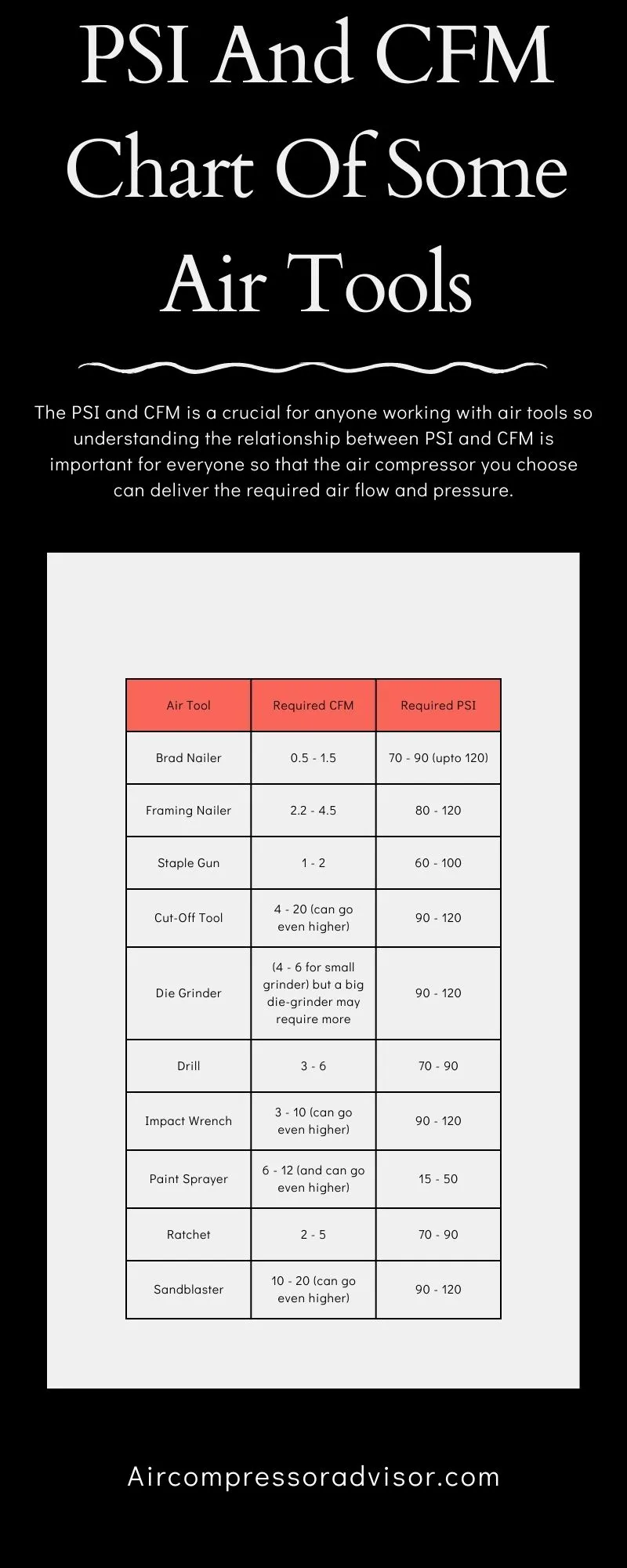

PSI And CFM Chart For Some Air Tools:

Here's a general chart to help you determine what type of air compressor you will need for common air tools:

Keep in mind that these are general guidelines, and the specific requirements of your air tools may vary so it's always best to consult the manufacturer's specifications for your tools to ensure that you select an air compressor that can meet their needs.

Frequently Asked Questions (FAQ):

What Is The Minimum CFM Required For Air Tools?

The minimum CFM required for air tools depends on the type of tool you are using. Small air tools like pneumatic drills and die grinders may require a minimum of 3-6 CFM, while larger tools like sanders and impact wrenches may require a minimum of 6-12 CFM. In the end, it will depend on which type of air tools you will be using so before getting them be sure to check their specifications.

How Much PSI Do I Need For My Air Tools?

The required PSI for air tools varies depending on the type of tool and its intended use, so it's important to consult the manufacturer's recommendations or specifications to ensure proper operation.

Can I Use A Smaller Compressor Than What Is Recommended For My Air Tools?

While you can use a smaller compressor than what is recommended for your air tools, it will not operate efficiently as a smaller compressor will not be able to deliver the required air pressure as well as volume and your tools may not work correctly.

How Do I Choose An Air Compressor For Air Tools?

When choosing an air compressor for air tools, consider factors such as the required CFM (cubic feet per minute) of airflow, the PSI (pounds per square inch) needed for your tools, the size and portability of the compressor, and your budget. It's best to choose a compressor that can output the necessary CFM and PSI for your most demanding tool but also consider if you need a portable or stationary compressor and what your budget allows for.

Can You Use A 12V Compressor For Air Tools?

You can use a 12v compressor for air tools, but it may not be suitable for high-demand tools that require a continuous supply of compressed air. A 12v compressor is typically designed for smaller applications such as inflating tires, etc. It's important to check the CFM and PSI ratings of the compressor and ensure they meet the requirements of your air tools before use.

Conclusion: Choosing the right size air compressor for your air tools is crucial for efficient and effective operation. By considering the type of tools you will be using, their air pressure and volume requirements, and the size of the air tank, you can determine which size air compressor to get for your needs. Remember to do the math to calculate the required CFM, PSI, and tank size to ensure that your air compressor can keep up with your tool's demands, and if you find this article helpful then share it and have an amazing day.

Related Post: