What Size Air Compressor For Nail Gun? (With Chart)

Air compressors are essential power tools for a variety of applications including powering nail guns as they can provide a consistent as well as a reliable source of compressed air to drive nails into various materials.

However, when it comes to choosing the right air compressor for this tool things can get a bit complicated so in this article, I will discuss the factors that determine what size air compressor is suitable for nail guns and help you choose the right one for your needs. So, without any further ado let's take a look at it.

Factors To Consider When Selecting an Air Compressor for Nail Guns:

CFM (Cubic Feet Per Minute):

CFM is the measure of the volume of air that an air compressor can deliver in a minute and it is an essential factor to consider when selecting an air compressor as it determines if the compressor can provide enough air to power your nail gun.

For example, a framing nailer may require a higher CFM than a finished nailer.

PSI (Pounds Per Square Inch):

PSI is the measure of the pressure of the air delivered by the compressor and it is also an essential factor to consider as it determines the force with which the nails will be driven into the material.

Nail guns typically require a minimum of 70-120 PSI to operate.

Tank Size:

The tank size of an air compressor is another important thing to consider as the tank's capacity determines how much compressed air is available to power the nail gun before the compressor has to refill.

The larger the air tank the longer you can operate the nail gun without interruption. However, larger tanks also mean heavier as well as bulkier compressors which may not be suitable for all job sites or storage spaces.

Duty Cycle:

The duty cycle of an air compressor refers to the amount of time the compressor can run continuously without overheating or causing damage. The duty cycle is as important as the above factors as continuous use of a compressor beyond its duty cycle can cause it to fail.

The duty cycle is typically expressed as a percentage of the total operating time and generally, it ranges from 33% to 100% and a compressor with a higher duty cycle is preferred for nail gun applications.

Portability:

Portability is another thing to keep in mind when looking for a compressor so if you have to move the compressor from one job site to another you will need a compressor that is lightweight and compact.

However, portable compressors may not be as powerful or have as large a tank size as stationary compressors so it is essential to find a balance between portability and functionality.

Horsepower:

Horsepower is the measure of the power output of the air compressor's motor and although horsepower is not a critical factor when selecting a compressor it can give an idea of the compressor's overall power.

A compressor with a higher horsepower rating can deliver more air at a higher pressure making it suitable for heavy-duty tasks.

Noise Level:

Air compressors can be quite noisy with some models producing up to 90 decibels of sound and if you plan to work in a quiet environment or have noise restrictions in your area it is essential to pick an air compressor with a low noise level.

So try to look for compressors that have a low noise.

Oil-Free vs. Oil-Lubricated Compressors:

Air compressors come in two types: oil-free and oil-lubricated. Oil-free compressors are easy to maintain and suitable for intermittent use while oil-lubricated compressors require regular maintenance but can handle continuous use.

So in terms of these two, it will depend upon your preferences as to what you are looking for in it.

Air Hose:

The air hose that connects the air compressor to the nail gun is also an essential factor to consider as the hose's diameter and length can affect the CFM as well as PSI delivered to the nail gun so it is important to select a hose that is compatible with your compressor as well as nail gun.

A larger diameter hose can deliver more air to the nail gun and reduce pressure drop while a longer hose can provide more flexibility along with reach.

Safety Features:

Safety is always a top priority when working with power tools and air compressors are no exception. So look for compressors with safety features such as automatic shut-off, pressure relief valves, and thermal overload protection.

These features can prevent accidents as well as protect the compressor from damage.

What Size Air Compressor for Nail Guns?

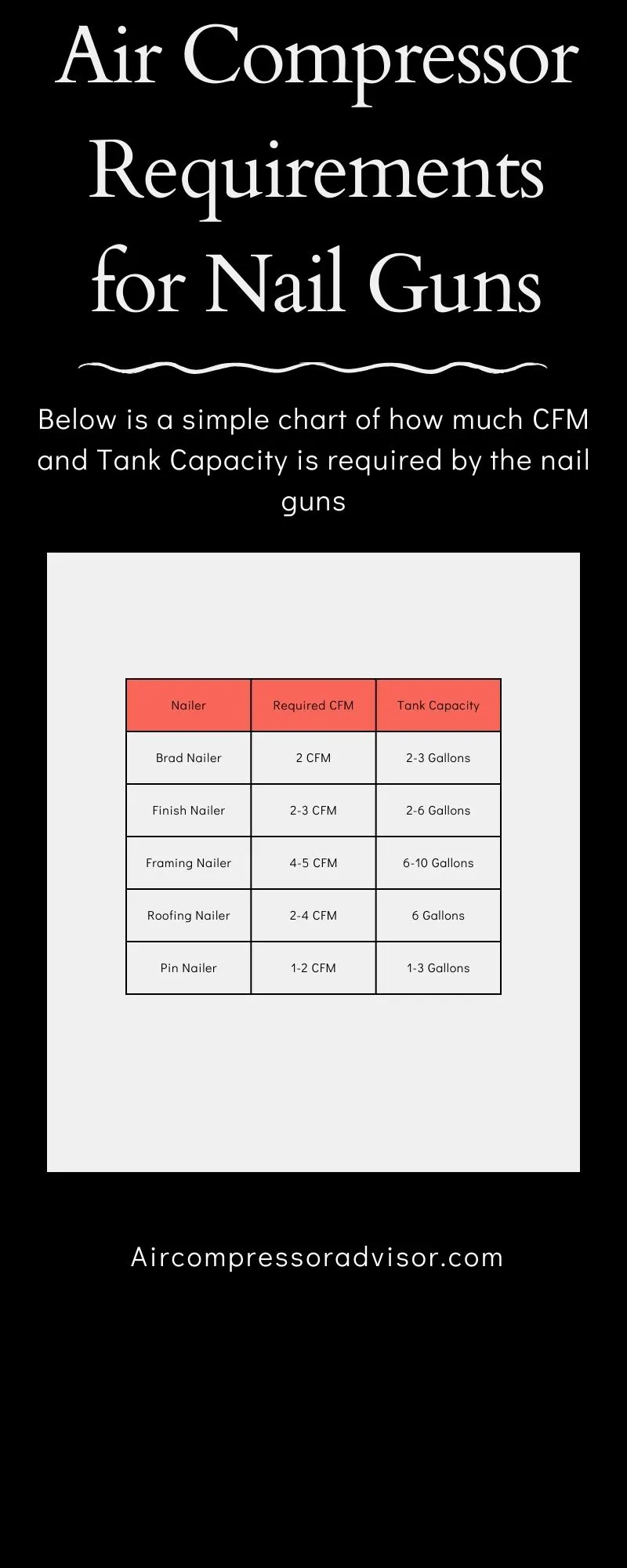

Now that we have discussed the factors to consider when picking an air compressor let's take a look at the recommended sizes for different types of nail guns.

Brad Nailer:

A brad nailer is a type of nail gun that is used for precise and delicate woodworking tasks such as attaching trim and molding.

A suitable air compressor for a Brad nailer should have a CFM of 2 and a tank size of 2-3 gallons.

Finish Nailer:

A finish nailer is a type of nail gun that is used for finishing tasks such as installing baseboards and crown molding, etc.

For a finish nailer, you should have a compressor with a CFM of 2-3 and a tank size of 2-6 gallons.

Framing Nailer:

A framing nailer is a type of nail gun that is used for heavy-duty tasks such as framing and building decks.

So for the framing nailer, you need to have a compressor with a CFM of 4-5 and a tank size of 6-10 gallons.

Roofing Nailer:

A roofing nailer is a type of nail gun that is used for roofing tasks such as installing shingles, tar paper, etc.

And for a roofing nailer, you will need a CFM of 2-4 and a tank size of about 6 gallons.

Pin Nailer:

A pin nailer is a type of nail gun that is used for delicate tasks and small applications.

In terms of pin nailer, you will be required a CFM of about 1-2 and a tank size of 1-3 gallons.

Frequently Asked Questions (FAQ):

Can I use a small air compressor for a framing nailer?

It's possible but is not the most efficient option. Instead, an air compressor with a tank size of 6-10 gallons and a max pressure output of 120-150 PSI is recommended for framing nailers.

How much PSI for 18 gauge Brad nailer?

An 18 gauge brad nailer typically requires a PSI (pounds per square inch) range of 70-120 to operate effectively.

What if my air compressor doesn't meet the required specifications for my nail gun?

You can upgrade to another compressor that meets the required specifications or adjust the pressure and volume settings on your nail gun to match the compressor's output.

Do I need a compressor for a nail gun?

Yes, most nail guns require a compressor to function as they rely on compressed air to drive nails into the material.

However, there are also cordless nail guns available that use battery power instead of compressed air.

Can I use an airless nail gun instead of an air-powered nail gun?

Yes, but airless nail guns require a power source like electricity or batteries.

How much psi for 16 gauge nailer?

A 16 gauge nailer typically requires a PSI range of 70-120 to operate effectively; however, it's important to check the manufacturer's recommendations for the specific nailer model as the required PSI may vary.

What other factors should I consider when choosing an air compressor for my nail gun?

Some other factors to consider are CFM, noise level, portability, along with durability.

How do I maintain my air compressor and nail gun?

Clean the air filter, drain the tank, check and change the oil, lubricate the nail gun, and check and replace nails as needed.

Conclusion:

Selecting an air compressor for nail guns is crucial to ensure that it operates efficiently so consider the CFM, PSI, tank size, duty cycle, portability, horsepower, noise level, air hose, and safety features when picking an air compressor for this tool.

A compressor with a higher CFM and tank size is preferred for heavy-duty tasks such as framing while a compressor with a lower CFM and tank size is suitable for delicate woodworking tasks such as attaching small trim.

Keep in mind that portable compressors may not be as powerful or have as large a tank size as stationary compressors so it is essential to find a balance between portability and functionality. If you find this guide helpful then share it and have a nice day.

Related Posts: